In the fast-paced world of modern engineering and automation, achieving precision and control is crucial for productivity and efficiency. High-quality pneumatic systems have become an essential part of this progress, offering reliable motion, smooth operation, and consistent performance across a wide range of applications. These systems deliver an ideal balance between power and flexibility, helping industries operate with accuracy and dependability.

Understanding the Value of Pneumatic Systems

Pneumatic systems use compressed air to transmit and control energy, powering tools, machines, and automated equipment. Their design makes them a preferred choice in many sectors because they are:

- Clean and efficient, using air as a renewable and readily available energy source.

- Reliable and low-maintenance, minimizing downtime and repair costs.

- Versatile, suitable for various applications, from manufacturing to automation.

- Safe and durable, reducing risks while maintaining consistent output.

By converting air pressure into mechanical motion, these systems ensure precise performance while keeping operations environmentally friendly.

Key Advantages of High-Quality Pneumatic Systems

Investing in premium pneumatic solutions leads to enhanced control, smoother performance, and long-term reliability.

- Accurate Motion Control: Enables precise movements for repetitive or delicate tasks.

- Energy Efficiency: Optimizes air usage to reduce energy consumption and operating costs.

- Reduced Downtime: Designed for durability and easy maintenance, ensuring continuous operation.

- Enhanced Productivity: Improves speed and consistency in manufacturing and assembly processes.

These benefits make pneumatic systems an indispensable choice for industries seeking both precision and performance.

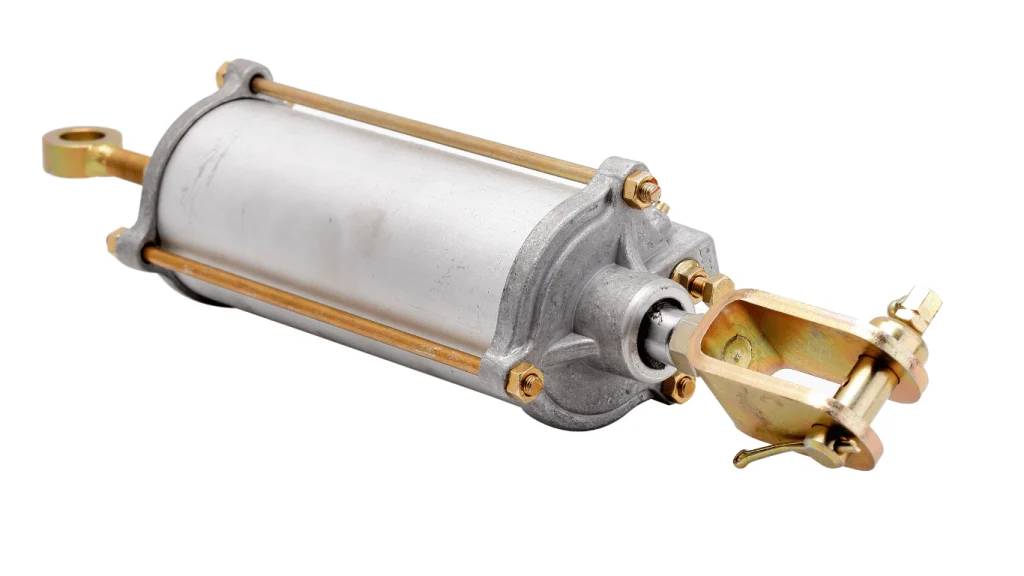

Innovative Components Driving Efficiency

Modern pneumatic systems are built with advanced components designed to optimize operation and adaptability.

- Actuators and Cylinders: Convert air pressure into linear or rotary motion for controlled movement.

- Valves and Regulators: Manage air flow and pressure, ensuring smooth system response.

- Air Preparation Units: Filter and regulate compressed air for maximum system life and reliability.

- Tubing and Fittings: Provide secure, leak-free connections that support system efficiency.

Each component works in harmony to deliver seamless automation and precise control in demanding environments.

Applications Across Diverse Industries

Pneumatic technology plays a vital role in multiple sectors, supporting innovation and performance:

- Manufacturing: Enhances assembly lines and robotic operations with accurate control.

- Automotive: Supports precision in part handling and automated assembly systems.

- Food and Beverage: Ensures hygienic, oil-free, and consistent motion control.

- Packaging and Processing: Provides speed and reliability for repetitive tasks.

This adaptability makes pneumatic definition systems an ideal solution wherever precision, safety, and efficiency are required.

Empowering the Future of Automation

As industries evolve toward smarter and more sustainable technologies, high-quality pneumatic systems will continue to shape the future of automation. By offering precise control, reliability, and energy efficiency, these systems empower organizations to achieve higher productivity and smoother operations. Embracing advanced pneumatic solutions means embracing a future of innovation, control, and long-term success.